| Quick Details | |

| Standard or Nonstandard: | Standard |

| Structure: | Angle |

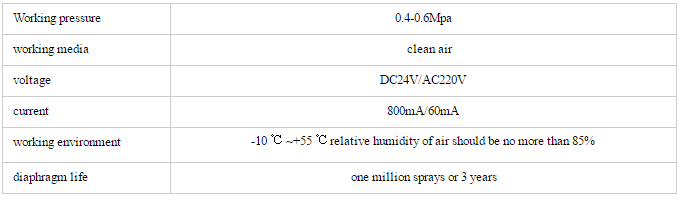

| Pressure: | 0.4-0.6Mpa |

| Power: | Solenoid |

| Material: | Alloy |

| Temperature of Media: | -10℃-55℃ |

| Media: | Clean air |

| Port Size: | Standard |

| Place of Origin: | China (Mainland) |

| Model Number: | DMF-ZM |

| Brand Name: | EO |

| Application: | General, General |

| Product name: | solenoid valve |

| Working pressure: | 0.4-0.6Mpa |

| Body material: | Aluminum Alloy |

| Usage: | Bagfilter |

| Dust filter part: | Pulse jet valve |

| Working medium: | Clean air |

| Type: | 2-way |

| Certificate: | ISO9001:2008 |

| Standard: | Yes |

One of the three types common used pulse valve DMF-ZM model is a nut connection structure which is improved on the basis of Z model pulse valve. DCF-ZM pulse valve features the favourable advantages of Z model valves such as high sensitivity, large air exhaust and stable performance, etc.

Work Principle

Electromagnetic pulse valve is composed of electromagnetic pre-head,diaphragm and valve body.The back cavity of the diaphragm is bigger than the front cavity.The diaphragm is kept at the closed position due to the effect of big pressure.

Electric control cabinet inputs electronic signal so that the electromagnetic armature attracts the moving bar.Unclose the balancing hole to release the pressure gas in the back cavity of the diaphragm quickly;the pressure gas in the font cavity holds up the diaphragm to open the passage and the pulse valve starts blowing.

The signal disappears and the spring of the armature works immediately to resume the moving bar so as to close the balancing hole.The pressure gas in the back cavity of the diaphragm and the spring work together to close the passage and the valve stops blowing.

The orifice in the diaphragm functions to damp the airflow when the moving bar of the armature holds up for balancing and to transit the air to the back cavity as soon as the balancing hole is shut to close the passage and stop blowing.

Feature

1. It has the same sensitivity and blowing performance with Z type angle valve.

2. It's connected to the inlet & outlet pipe by the compact sealing double nut to ensure.

3. Matching movable connector has been used to ensure the valve will not come apart when the valve moves during cleaning.

Our Service

Spot delivery, including delivering small batches of goods

Provide wide-range and complete materials series products

Cutting plates, including complex shapes of materials and special processing and disposal

Cutting bars and strips

Our application technology expert provide the best material and recommendation

One-stop service