| Quick Details | |

| Standard or Nonstandard: | Standard |

| Structure: | Ball |

| Pressure: | 0~1.6Mpa |

| Power: | Electric |

| Material: | Stainless steel, Stainless steel |

| Temperature of Media: | -10℃~180℃ |

| Media: | water, liquid, neutral gas, oil, steam, weak acid or week alkali solut |

| Port Size: | G3/8"~G4" |

| Place of Origin: | China (Mainland) |

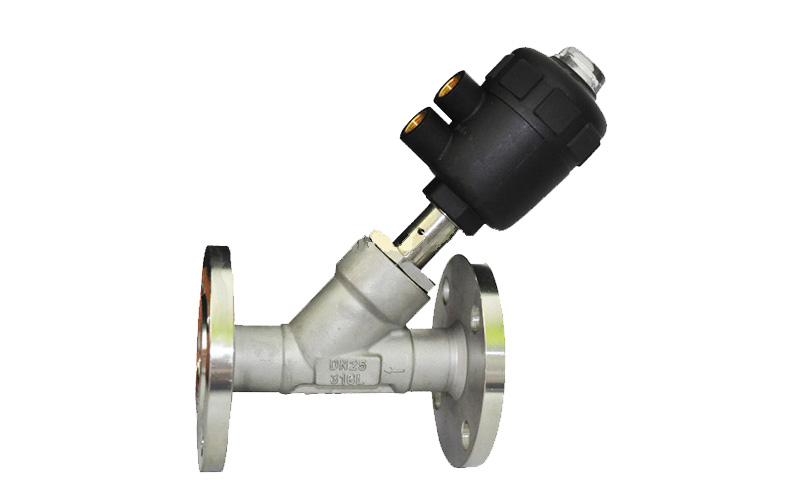

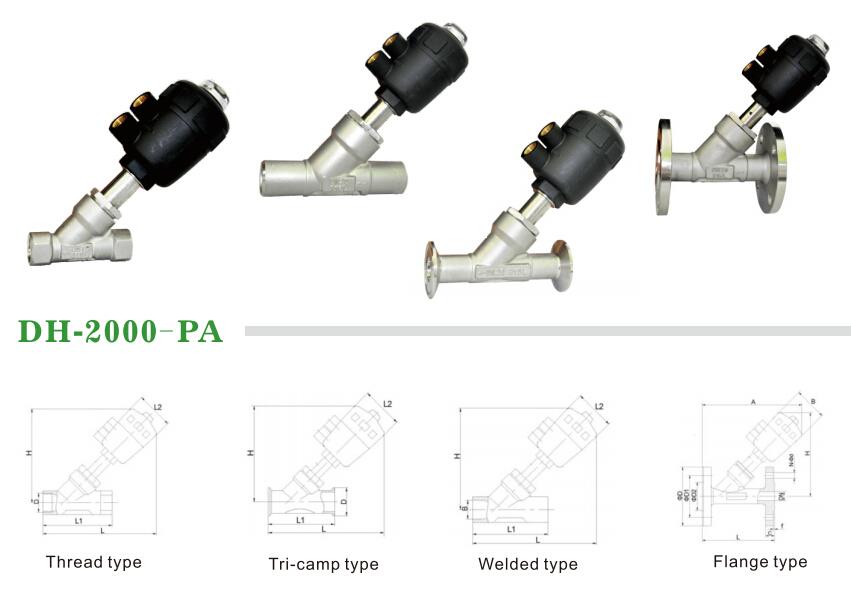

| Model Number: | DH2000 |

| Brand Name: | EO |

| Application: | General |

| Certifications: | CE, ROHS, ISO, TUV |

| Quality warranty: | One year guarantee |

| Staff: | 200-500 |

| Connection: | Threaded/Weld/ANSI flange/Tri-clamp |

| Order lead time: | 7~15 day after the payment is finished |

| Sample leadtime: | 2-3 days |

Pneumatic Angle Seat Valve DH2000 Series

Design Character

High flow rate due to the angle seat configuration.

Anti-water hammer feature with the fluid entry below the seat.

Stainless steel body and corrosion resistant actuator.

The pneumatic actuator can be rotated through 360 degrees.

Optical position indicator

Internal seals are self adjusting for long life, no need maintenance

Easily convertible from N.C. to N.O. or double acting

Universal mounting-any mounting orientation is acceptable

Application

Steam Applications

Air Drying equipment

Process Control Applications

Sterilizers and autoclaves

Laundry Equipment

Textile Dyeing & Drying

Bottling & Dispensing Equipment

Industrial project

Ink & Paint Dispensing

Chemical and Petrochemical Industries

Paper and pulp Industries

Cooling system

Nuclear Energy

Specifications:

Orifice: DN10-DN100

Thread: G3/8”~G4”

Port connection: Threaded/Weld/ANSI flange/Tri-clamp

Body material: Stainless steel

Actuator material: Plastic or stainless steel

Valve core seal: PTFE

Valve steam seal: PTPE, Viton

Application medium: water, liquid, neutral gas, oil, steam, weak acid or week alkali solution

Medium temperature: -10℃~180℃

Environment temperature: 10℃~60℃

Viscidity: Max.600mm2/s

Installation: any position

Controlling medium: air or neutral gas

Controlling pressure range: 0.3~1Mpa

Liquid Working pressure: 0~1.6Mpa

Our Service

Spot delivery, including delivering small batches of goods

Provide wide-range and complete materials series products

Cutting plates, including complex shapes of materials and special processing and disposal

Cutting bars and strips

Our application technology expert provide the best material and recommendation

One-stop service