Products Details :

Shenyang EO Valve Co.,Ltd is a leading China casting pressure seal gate valve with bypass manufacturer and supplier, and as a professional company, we have productive factory to offer you good price and service.

Products Description :

Shenyang EO Valve Co.,Ltd is a leading China casting pressure seal gate valve with bypass manufacturer and supplier, and as a professional company, we have productive factory to offer you good price and service.

Casting Butt Weld Pressure Seal Bonnet Gate Valve.

Product Specifications :

Standards:

1. Design: API 600 / ASME B16.34 / BS 1414

2. Pressure-temperature Rating: ASME B16.34

3. Face to face dimensions: ASME B16.10

4. Pressure Range: Class 150~1500

5. Size Range: 2 inch~36 inch

Design Features:

1. Pressure Sealing design

2. Wedge type: flexible wedge

, double Wedge

3. Back seat design

4. Outsied screw and yoke(O.S&Y)

5. Body gasket: smooth ellipse composite gasket for class 150; half-groove spiral wound gasket for class 300;

Full-groove spiral wound gasket for class 600; octagonal ring gasket and oval ring gasket for class 900~class 1500

Material:

1. Cast Steel: A216 WCB, A105(<2" forged material)

2. Low temperature: A352 LCC, LCB,

3. Stainless steel: A351 CF8M, CF8, CF3M, CF3

Other material are available upon customer’s request

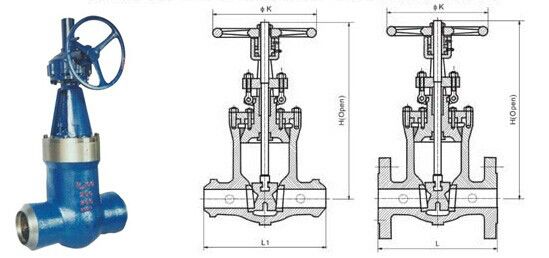

Technical Drawing:

Our Advantage:

1). Scale: 82,000.00 square meters non-dust workshop

2). The foundry is built to promise our raw material better before production.

3). Equipment: 350 sets advanced machining facilities, 5 automatic production lines

4). R&D: valve research and design center

5). Strict QC system is set up for the superior quality guarantee.

PACKAGING & DELIVERY

Packaging details : electric actuated butterfly valve: the strong plywood cases or as per the customer's request.

Delivery details : 4-5 weeks after receipt of down payment by T/T

Payment : T/T, L/C, Western Union and PayPal

FAQ :

1. What is your difference from other competitors?

1). Scale: 82,000.00 square meters non-dust workshop

2). Condition: good after sale service

3). Equipment: 350 sets advanced machining facilities, 5 automatic production lines

4). R&D: valve research and design center

2. How do you control your quality?

1). The foundry is built to promise our raw material better before production.

2). Strict QC system is set up for the superior quality guarantee.