| Quick Details | |

| Standard or Nonstandard: | Standard |

| Structure: | Control |

| Pressure: | Medium Pressure |

| Power: | Pneumatic |

| Material: | Alloy, Casting, Stainless Steel |

| Temperature of Media: | -196℃~+593℃ |

| Media: | Fluid and gas |

| Port Size: | Standard |

| Place of Origin: | China (Mainland) |

| Brand Name: | EO |

| Application: | industrial |

| Nominal Size: | DN15~DN400 |

| Operating Temperature: | -17℃ ~ +260℃ |

| Nominal Pressure(NA&SA): | PN20,50,110 |

| Nominal Pressure(EU): | PN16,40,63 |

| Characteristic: | Equal percentage, Linear, On/off |

| Rangeability: | 50:1 |

| Seat Leakage: | Class IV, V according to GB/T |

| Nominal Size | DN40~DN300 |

| Operating Temperature | -17℃~+260℃ |

| Nominal Pressure | American Standard : PN20(ANSI 150), 50(ANSI 300) European Standard : PN16, 25, 40 |

| Characteristic | Equal Percentage, Linear |

| Seat Ieakage | Class IV, V, VI according to GB/T 17213.4-2005/IEC 60534-4:2006 |

| Rangeability | 50:1 |

Product Advantage

1. Valve Trims

According to the needs of the working conditions, different materials and surface hardening treatment can easily be chosen to meet the requirements of each function module of trim to improve its performance of the corrosion, cavitation and erosion resistant, lengthen service life.

2. Valve body

The body of LN8 series control valves consists of two passages from upper and lower, forming a shape like letter "S". The design of an elliptical section reduces the flow resistance and turbulent flow to keep the flow fluent. The flap in the middle of upper passage can reduce the eddy flow and increase the flow capacity.

3. Actuator

The standard mate of LN8 series is AM8 Multi-spring pneumatic diaphragm actuator, which can be used in many conditions with the features of strong output force, high reliability, long lifespan and extensive application. The output force changes with the number of springs. The high stress resistant diaphragm, bearing maximum pressure of 0.5 MPa air supply, gives control valve a reliable shutoff. This type of actuator has a long life cycle with more than 1 million times.

Well Sealed

1. Structure

A. New function modular design B. Self-centring seat design

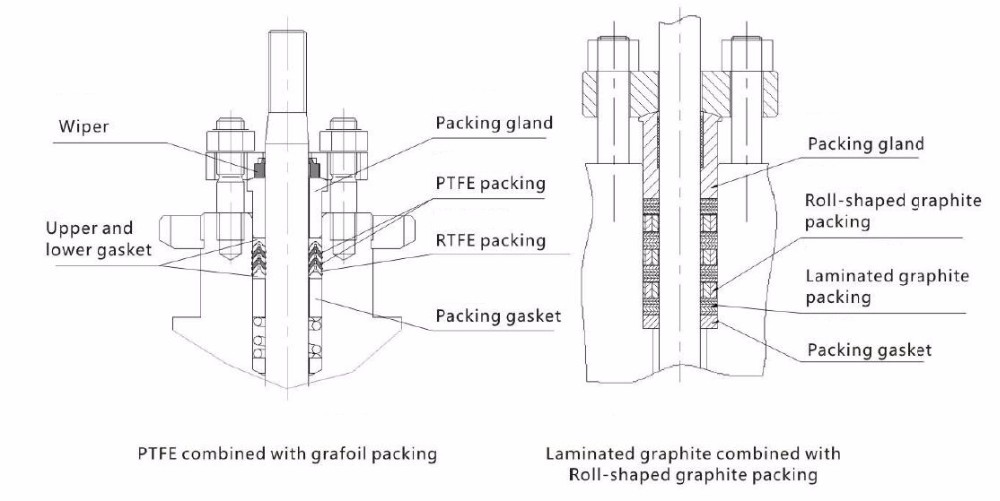

2. Packing system

The packing box assemblies are also optimized. Seal ring in the gland flange can prevent the dirt from entering and protect the packings. The V-ring is added with an U-groove and its angle is changed from conventional 90 to more efficient 85. The packing is a combination of alternating pure PTFE and PTFE with grafoil. When the temperature of fluid is above 200℃, the packing will be made by grafoil.

High Precision

LN8 series control valves are designed strictly on the basis of the IEC standard. They are the latest self-innovated modularized straight stroke control valve of EO We divide the trims into three modules, namely guide, control and seal module. We provide the best solution according to the function of each module and make action, control and seal more reliable.

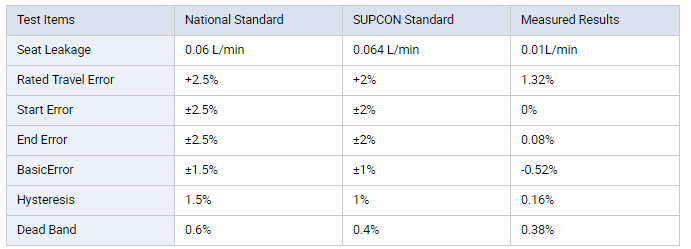

Each index, linear, hysteresis, dead zone and leakage, for example, is full compliance with national standards.

Note: For below measured results, take LN8100 top guide single seat valve (PN110) as an example.

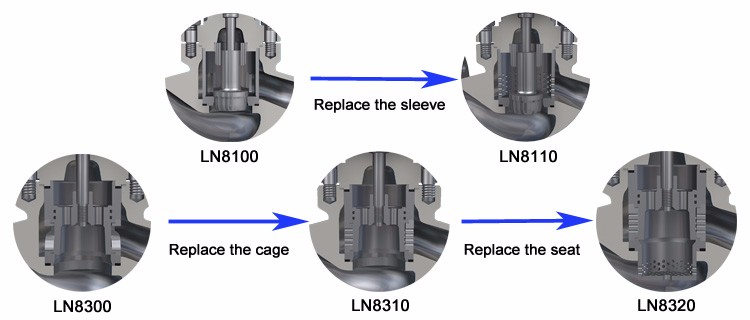

Easy to maintain

The unique platform and modul design make it easy to remove and displace the parts without special tools, and moreover, easy to change the type of the valve only by changing few parts. A variety of material combinations is optional for the parts.

Our Service

Spot delivery, including delivering small batches of goods

Provide wide-range and complete materials series products

Cutting plates, including complex shapes of materials and special processing and disposal

Cutting bars and strips

Our application technology expert provide the best material and recommendation

One-stop service