Products Details :

Shenyang EO Valve Co.,Ltd is a leading China socket weld pressure sealing check valve, sewage check valve manufacturer and supplier, and as a professional company, we have productive factory to offer you good price and service. Fujian Province Datong Reciprocity Valve...

Products Description :

Shenyang EO Valve Co.,Ltd is a leading China socket weld pressure sealing check valve, sewage check valve manufacturer and supplier, and as a professional company, we have productive factory to offer you good price and service.

Cast Steel Pressure Sealing Swing Check Valve Flange Connection.

SPECIFICATION :

1. DESIGN AND MANUFACTURE: | BS 1868/ASME B16.34/API 6D |

2. FACE TO FACE DIMENSIONS: | ASME B16.10 |

3. FLANGE ENDS DIMENSIONS: NPS1/2”-24” |

ASME B16.5 |

NPS 26”-36” | ASME B16.47 |

4. BW ENDS DIMENSIONS: | ASME B16.25 |

5. PRESSURE-TEMPERATURE RATINGS: | ASME B16.34 |

6. NORMAL PRESSURE: | CLASS 900~2500 |

7. NORMAL DIAMETER: | NPS 2″~24″ |

Design Feature :

1. Pressure Seal Bonnet(PSB) Design

2. Swing Disc: Disc Is Fastened Securely To Disc Hanger With a Lock Nut And Copter Pin

3. Seat Type: Welder Seat Or Integral Seat

4.Application:Chemical, Petrochemical, Oil & Gas, Power Plant, General Industry etc.

5.Temperature rating:-45°C - + 650 °C or above

6.Cryogenic, Full port

7.BW, SW or Flange ends are available

8.Renewable Seat Rings, Low Emission

9.Pressure Rating:900LB-2500LB

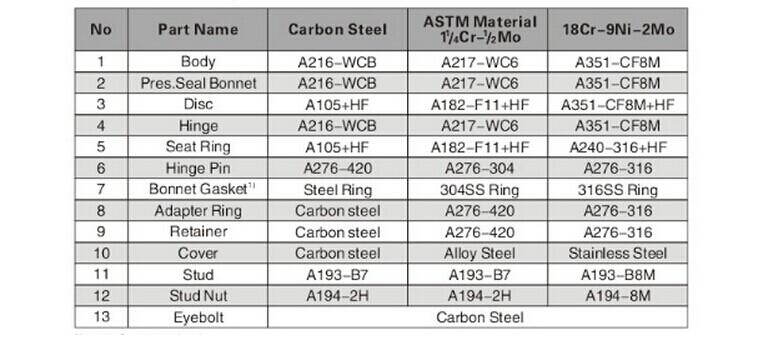

Main Material:

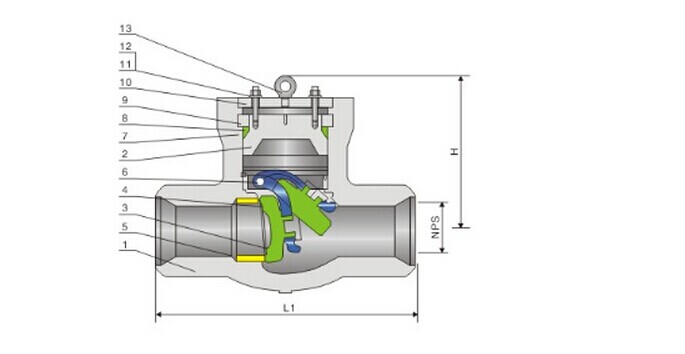

Structure Drawing(For reference) :

Our Advantage :

1). Scale: 82,000.00 square meters non-dust workshop

2). The foundry is built to promise our raw material better before production.

3). Equipment: 350 sets advanced machining facilities, 5 automatic production lines

4). R&D: valve research and design center

5). Strict QC system is set up for the superior quality guarantee.

PACKAGING & DELIVERY

Packaging details : electric actuated butterfly valve: the strong plywood cases or as per the customer's request.

Delivery details : 4-5 weeks after receipt of down payment by T/T

Payment : T/T, L/C, Western Union and PayPal